Hydraulic elevators and hydraulic monitors for industrial PGSH devices

The LLC "OrMag" company conducts contract production of hydraulic elevators and hydraulic monitors operated in combination with PGSH devices (hydroelevator sluice device).

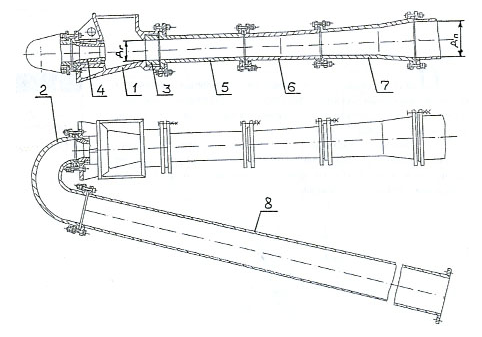

Hydroelevators (water lifts, jet pumps) are widely used in the development of placer deposits for lifting sands to washing devices. Previously, the sands are washed away with the help of a hydromonitor and large pebbles (galya) are separated from them. The hydraulic elevator receives pulp with a maximum size of 100-130 mm (feed size). The structure of the hydraulic elevator includes:

Neck - see 5

Bell - see 7

Insert - see 3

Receiving chamber - see 1

Nozzle - see 4

Knee - see 2

Transition - see 6

Diffuser Nuts

Connecting flanges

Hydroelevators (water lifts, jet pumps) are widely used in the development of placer deposits for lifting sands to washing devices. Previously, the sands are washed away with the help of a hydromonitor and large pebbles (galya) are separated from them. The hydraulic elevator receives pulp with a maximum size of 100-130 mm (feed size). The structure of the hydraulic elevator includes:

Neck - see 5

Bell - see 7

Insert - see 3

Receiving chamber - see 1

Nozzle - see 4

Knee - see 2

Transition - see 6

Diffuser Nuts

Connecting flanges

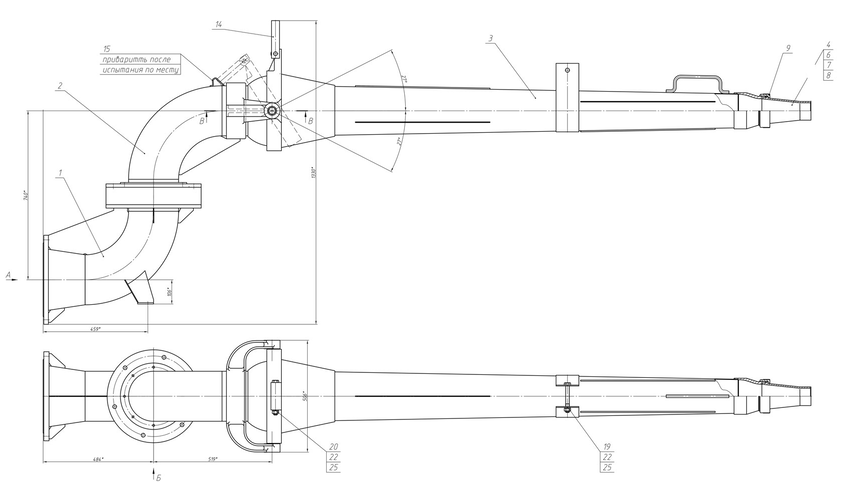

Hydraulic monitors are used in alluvial gold mining for the erosion of rocks on the table of the hydraulic head, as well as for the erosion of loose rocks in the rear. Monitors with manual control are used to work as part of hydro-cardiac flushing devices. The control is carried out manually by a driver (pipe or beam) with a length of 4 to 6 m, which is simultaneously a counterweight. In principle, the hydraulic monitor consists of a lower knee, a horizontal rotation hinge, an upper knee, with a vertical lifting ball joint, a barrel and a replaceable nozzle, which is attached to the trunk with a cap nut. On the upper part of the lower knee, a glass is installed that wraps around the hinge of the horizontal rotation. The hinge makes it possible to rotate the upper knee with the barrel 360°. Horizontal rotation and vertical lifting hinges have rubber seals. The conical barrel narrows the section of the jet. The force is transmitted to the upper knee through the bracket 6.

Hydraulic elevators

Hydraulic monitors

Форма регистрация

Зарегистрируйтесь для получения полного доступа к функционалу сайта

Отправляя данные вы соглашаетесь с политикой обработки персональных данных. Актуальная версия Политики в свободном доступе расположена в сети Интернет по адресу https://ormagural.ru/pers-data

Заказ на производство

Сделайте заказ, указав краткое описание, при наличии чертеж или эскиз. Мы обязательно свяжемся с Вами

Отправляя данные вы соглашаетесь с политикой обработки персональных данных. Актуальная версия Политики https://ormagural.ru/pers-data